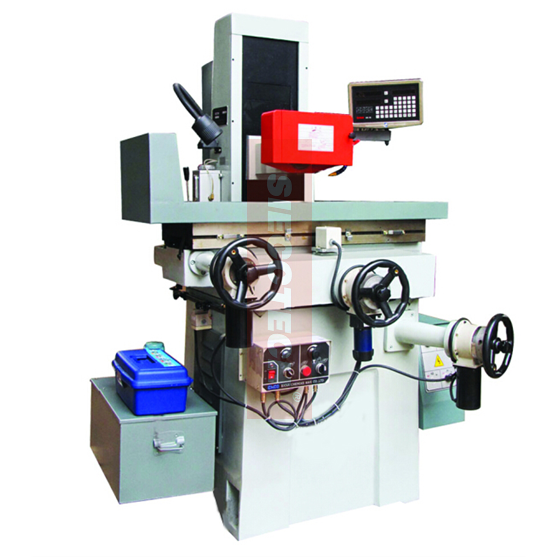

Characteristics of machine tools:

Based on manual surface grinder, it covert the longitudinal and vertical machine to fully automatic The bidirectional friction electronic clutch, simple and reliable structure, clutch reversing process has no impact, no noise, safe commutation 5000000 times; the electric control part with electronic switching frequency switching, The service life 10 times longer than the relay control, simple operation, sensitive, infinitely variable; large output torque, low noise, Safe and reliable. Power supply use a number of mechanical and electrical protection function which is safe voltage, Energy saving, power saving, power consumption per class (calculated according to 8 hours) is only 0.6.When the manual grinding is working,Before and after the workbench’s movement, in and out, around the reversing are automatic operation, greatly improving the

production’s efficiency and the surface finish, suitable scope that from the original single, small batch to mass batch.

机床特性:

是在手动平面磨床的基础上,将工作台手动的纵向运动机构和横向运动机构转换为全自动.采用双向摩擦电子合器,结构简单、可靠,离合换向过程无冲击、无噪音,可安全换向500万次以上;电控部分用电子开关实现频繁切换,寿命比继电器控制长10倍,操作简单项、灵敏、无级变速;输出力矩大,噪音低。安全可靠,使用电源为安全电压,且使用多项机械、电子保护功能。节能、省电,耗电量平均每班(按8小时计算)仅为0.6度。使手动平磨在进行磨削时,工作台(工件)左右和前后的运动、进给、换向实现自动化操作,大大提高了生产效率和磨削光洁度,使的适用范围由原来的单件、小批量磨削扩大到大批量磨削。

| Model 型号 | MD820 | |||

| Bench 工作台 | Max.workpiece to be Ground (L×W×H) 工作台台面尺寸 (长×宽) | mm | 480×200 | |

| Maximum travel of table (L × W) 工作台最大行程 (长×宽) | mm | 530×220 | ||

| Table maximum cutting area (L × W) 工作台最大切削面积 (长×宽) | mm | 520×220 | ||

| Number of T -Slot 工作台T型槽 (槽数×槽宽) | mm | 1×14 | ||

| The grinding head 磨头 | Distance From Table Surface To Spindle Center 砂轮轴中心线至工作台面距离 | m | 450 | |

| Wheel Size(dia×width×bore) 砂轮(WA46K5V)尺寸 (外径×宽×内径) | mm | ø200×20×ø31.75 | ||

| Spindle speeds 砂轮转速(50HZ) | r/m | 2850 | ||

| The amount of feed 进给量 | Table longitudinal (left and right) speed (stepless) 工作台纵向(左右)速度(无级) | /min | 3--20 | |

| Table horizontal (before and after) the amount of feed 工作台横向(前后)进给量 | Continuous (variable speed)连续(无级调速) | m/min | 150 | |

| Intermittent (stepless) 断续(无级调速) | m/次 | 0-5 | ||

| The handwheel rotates 手轮每转 | mm | 2.5 | ||

| Hand wheel each grid 手轮每格 | mm | 0.02 | ||

| Vertical (up and down) feed wheel feed 垂直(上下)进给手轮进给量 | The handwheel rotates 手轮每转 | mm | 1.25 | |

| Hand wheel each grid 手轮每格 | mm | 0.01 | ||

| Reversing feeder 换向进给器 | The total input power 总输入功率 | W | 150 | |

| X- feeder output speed. X-进给器输出转速转 | /min | 0--225 | ||

| X- feeder size X-进给器尺寸 | m | 280×130×120 | ||

| Y- feeder output speed. Y-进给器输出转速转 | /min | 0--120 | ||

| Y- feeder size M Y-进给器尺寸 | m | 280×130×120 | ||

| Motor power 电机功率 | Spindle motor 主轴电机 | kw | 1.5 | |

| Cooling motor 冷却电机 | kw | 0.4 | ||

| Working precision 工作精度 | The machined surface of the base of parallelism 加工表面对基面的平行度 | m | 300/0.005 | |

| Surface Roughness 表面粗糙度 | μm | Ra0.32 | ||

| Weight of machine 机床重量 | Net 净重 | kg | 800 | |

| Cross 毛重 | kg | 890 | ||

| Packing Size (L×W×H) 包装尺寸(长×宽×高) | m | 1680×1200×1900 | ||